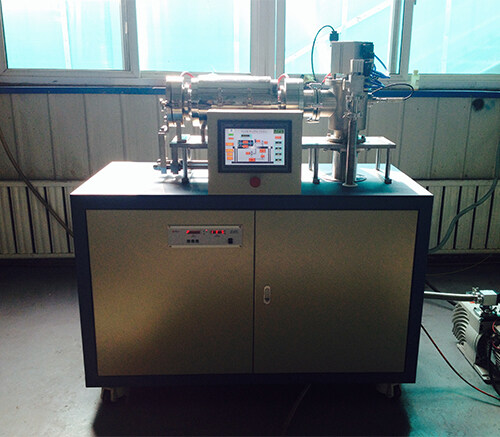

Vacuum Infrared Brazing Furnace

1. Vacuum Infrared Brazing Furnace is suitable for brazing stainless steel and other tools in a vacuum environment.

2. Vacuum Infrared Brazing Furnace has a high vacuum and high temperature.

3. Vacuum Infrared Brazing Furnace uses infrared radiation heating.

- Information

Product introduction of Vacuum Infrared Brazing Furnace:

Infrared High Temperature Vacuum Brazing Furnace is a device used for brazing materials, which can join two or more materials together in a vacuum environment by using infrared radiation heating. An infrared Brazing Furnace generally consists of a heating chamber, a vacuum system, a control system, and an observation window.

During the brazing process, you can directly place the material into the heating chamber and heat the material through the infrared radiation heater in the heating chamber to the brazing temperature. The Infrared Vacuum Furnace has strong vacuum properties and the vacuum environment is also one of the highlights of this product. Maintaining a vacuum environment during the brazing process can prevent the material from oxidative discoloration or other contaminants. Able to maintain the quality and stability of welding materials.

Product Benefits of Vacuum Infrared Brazing Furnace:

1. The Infrared Brazing Furnace has a compact structure and uses infrared heating tubes for heating. It has a fast heating speed and is suitable for high-temperature brazing of materials.

2. Infrared Vacuum Furnace has a precise temperature control systemthat can accurately control the heating temperature and time according to different brazing materials and requirements, to achieve high-quality brazing joints.

3. The side door of the Infrared High Temperature Vacuum Brazing Furnace opens, making it easy to enter and exit materials. The entire process of vacuuming, heating/cooling, is automatically controlled.

4. The average temperature zone size of the Vacuum infrared brazing furnace can be customized according to customer requirements to meet your individual needs.

5. Vacuum infrared brazing furnace has vacuum properties, which can ensure the welding brazing materials.

Product Specifications of Vacuum Infrared Brazing Furnace:

| Installation form | horizontal |

| Heater distribution method | Perimeter distribution |

| Heater material | Infrared heating tube |

| Insulation Materials | Mullite felt, etc. |

| maximum temperature | 1000℃ |

| Temperature control accuracy | ±1℃ |

| temperature uniformity | ±5℃ |

| Ultimate vacuum degree | 5×10 -4Pa |

| Average temperature zone size | Customized according to customer requirements |

| control method | automatic / manual |

Produced in our company's factory:

As a company that produces various types of vacuum application equipment, the factory has always played a vital role in our company's machinery production. Factory production has always been the core business of our company, involving a series of connections such as manufacturing, assembly, and design. First of all, our production starts from the design stage. Our team will design vacuum equipment that meets the requirements according to market changes and customer needs. During the design process, we will take into account the various functions, performance, and safety of the equipment. Other aspects to ensure the reliability of the product.