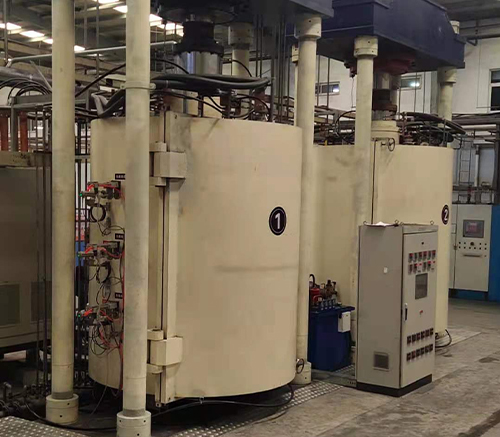

LED Fluorescent Powder Sintering Furnace

1. The LED Fluorescent Powder Sintering Furnace can maximize the use of energy.

2. The LED Fluorescent Powder Sintering Furnace meets environmental protection requirements.

3. The LED Fluorescent Powder Sintering Furnace is simple and convenient to operate.

- Information

Product introduction of LED Fluorescent Powder Sintering Furnace:

The phosphor powder sintering furnace is equipment used to manufacture LED phosphor powder. LED phosphor is a key material used in LED lighting and display devices. It has the advantages of high luminosity efficiency, bright colors, and long life. Phosphor powder sintering equipment is an equipment that processes raw materials through a sintering process to form granular LED phosphor powder.

Phosphor powder vacuum sintering consists of a furnace body, heating system, control system, exhaust system, and cooling system. The Phosphor powder sintering furnace has the characteristics of high temperature stability, temperature control accuracy, and uniform heating to meet the requirements of LED phosphor powder manufacturing process.

Product advantages of LED Fluorescent Powder Sintering Furnace:

1. Our Phosphor powder sintering furnace can be selected according to different scales and LED phosphors used in different fields to meet your various needs.

2. The manufacture of LED phosphor powder requires a high-temperature sintering process. Our Phosphor powder sintering equipment can stably provide a high-temperature environment to ensure the sintering effect and quality of the phosphor powder.

3. Our phosphor powder vacuum sintering adopts an efficient heating system, which can evenly heat the phosphor powder to avoid product quality problems caused by uneven temperature.

4. This sintering powder sintering furnace has high production efficiency and its ability to quickly heat up and cool down can shorten the sintering cycle and improve production efficiency.

Product specifications of Phosphor powder sintering furnace:

| Installation form | horizontal |

| Heater distribution method | Circular distribution/six-sided distribution |

| Heater material | Graphite/tungsten/molybdenum/tantalum/nickel-chromium alloy, etc. |

| Insulation Materials | Hard carbon felt/tungsten, molybdenum reflective screen/mullite felt, etc. |

| maximum temperature | 2300℃ |

| Temperature control accuracy | ±1℃ |

| temperature uniformity | ±5℃ |

| Ultimate vacuum degree | 5×10 -4Pa |

| Maximum gas pressure | 10 MPa |

| Average temperature zone size | Customized according to customer requirements |

| control method | automatic / manual |

Comfortable office environment:

Our company attaches great importance on the comfort of our employees' office environment. To this end, we strive to create a pleasant office environment to improve employee work efficiency and satisfaction.

Our office is full of modern design in order to provide employees with a comfortable and pleasant working space. Here, we also attach great importance to the reasonable layout of space to ensure that each employee has enough work space and privacy.