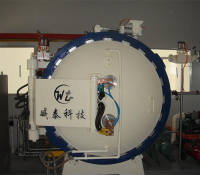

Vacuum High Pressure Sintering Furnace

1. The Vacuum High Pressure Sintering Furnace has a uniform temperature and can be accurately controlled.

2. The Vacuum High Pressure Sintering Furnace can be customized according to meet user requirements.

3. The Vacuum High Pressure Sintering Furnace adopts a horizontal installation form.

- Information

Product introduction of Vacuum High Pressure Sintering Furnace:

Vacuum atmosphere sintering furnace can sinter materials at high temperature and pressure, is suitable for high temperature nitriding (or other gas compositions) and prevents materials from decomposing under vacuum applications.Vacuum atmosphere sintering furnace combines vacuum technology and high-pressure atmosphere technology to sinter materials at high temperatures to make them have higher density and strength.

Vacuum atmosphere high pressure sintering system is widely used in powder metallurgy, ceramics, metal materials, semiconductor materials and other fields, and can be used to prepare high-performance materials and components.

The benefits of Vacuum High Pressure Sintering Furnace:1. Our Vacuum high pressure atmosphere sintering furnace can achieve a high vacuum or inert atmosphere, effectively preventing materials from reacting with oxygen and other gases at high temperatures, and avoiding impurities pollution and oxidation.

2. Our Vacuum atmosphere sintering furnace can provide better sintering parts by adding a high-pressure atmosphere, such as hydrogen, nitrogen, etc., to promote bonding between material particles and improve the sintering effect.

3. This Vacuum atmosphere high pressure sintering system can reach extremely high temperatures in the furnace cavity and can meet the needs for high-temperature sintering of various materials.

4. Our Vacuum high pressure atmosphere sintering furnace can obtain higher material densities and strength through vacuum and high-pressure atmosphere control, improving the performance and quality of materials.

Product Specifications of Vacuum High Pressure Sintering Furnace:

| Installation form | horizontal |

| Heater distribution method | Circular distribution/six-sided distribution |

| Heater material | Graphite/tungsten/molybdenum/tantalum/nickel-chromium alloy, etc. |

| Insulation Materials | Hard carbon felt/tungsten, molybdenum reflective screen/mullite felt, etc. |

| maximum temperature | 2300℃ |

| Temperature control accuracy | ±1℃ |

| temperature uniformity | ±5℃ |

| Ultimate vacuum degree | 5×10 -4Pa |

| Maximum gas pressure | 10 MPa |

| Average temperature zone size | Customized according to customer requirements |

| control method | automatic / manual |

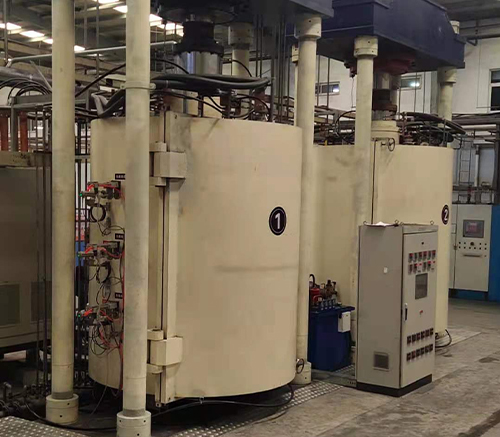

Produced in our company's factory:

As a company that produces various types of vacuum application equipment, the factory has always played a vital role in our company's machinery production. Factory production has always been the core business of our company, involving a series of connections such as manufacturing, assembly, and design. First of all, our production starts from the design stage. Our team will design vacuum equipment that meets the requirements according to market changes and customer needs. During the design process, we will take into account the various functions, performance, and safety of the equipment. Other aspects to ensure the reliability of the product.