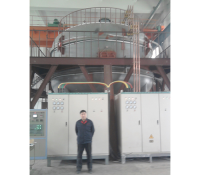

Vertical Vacuum Sintering Furnace

1. The Vertical Vacuum Sintering Furnace is widely used.

2. The Vertical Vacuum Sintering Furnace is especially suitable for sintering and processing high-temperature materials.

3. The Vertical Vacuum Sintering Furnace has important application value in the preparation of high-performance materials.

- Information

Product introduction of Vertical Vacuum Sintering Furnace:

Vertical vacuum sintering furnace is suitable for high temperature vacuum/atmosphere sintering or vacuum heat treatment of materials, which is used in hard alloy, magnetic alloy, ceramic and powder material industry. The door under the furnace body, hydraulic or electric lifting in and out of the material, vacuuming and heating/cooling process can be controlled automatically.

Equipment that meets different requirements of vacuum Sintering, vacuum Annealing, Quenching of true air, vacuum Brazing, and so on, can be customized according to needs.

Vertical Vacuum Sintering Furnace product advantages:

1. The furnace cavity of our vertical vacuum sintering equipment is equipped with a heating element, which can achieve uniform heating of materials and maintains consistency of the sintering effect.

2. This Vertical Sintering Furnace has undergone strict quality inspections during production to ensure the quality of the product.

3. Our vertical sintering furnace is equipped with a monitoring and control system for parameters such as temperature, pressure, and time, which can realize automatic control and adjustment and improve production efficiency and product quality.

4. This Vertical vacuum sintering equipment adopts a vertical structure, which can save floor space.

5. In order to facilitate your operation, our vertical sintering furnace is also equipped with atmosphere control, rapid cooling, and other functions to meet your processing needs for different materials.

Product Specifications of Vertical Vacuum Sintering Furnace:

| Installation form | horizontal |

| Heater distribution mode | Circular distribution/six-sided distribution |

| Heater material | Graphite/tungsten/molybdenum/tantalum/nickel chromium alloy, etc |

| Thermal insulation material | Hard carbon felt/tungsten, molybdenum reflective screen/mullite felt, etc |

| Maximum temperature | 2300℃ |

| Temperature control precision | ±1℃ |

| Temperature homogeneity | ±5℃ |

| Limit vacuum degree | 5×10-4Pa |

| Size of average temperature zone | Customized according to customer requirements |

| Mode of control | Automatic/Manual |

High-quality service guarantee:

Our company has always attached great importance on providing customers with high-quality service guarantees and considers all aspects from the user's perspective.

Regarding product quality assurance: The products produced by our company have undergone strict quality testing and quality control to ensure that the products meet customer needs. We use advanced manufacturing processes to ensure product reliability and durability.