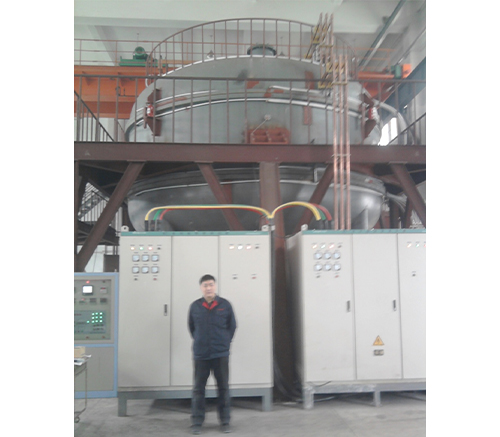

Silicon Dioxide Sintering Furnace

1. The Silicon Dioxide Sintering Furnace has strong environmental adaptability.

2. The Silicon Dioxide Sintering Furnace can accurately control temperature.

3. The Silicon Dioxide Sintering Furnace has a good sintering effect.

- Information

Product introduction of Silicon Dioxide Sintering Furnace:

Silica sintering furnace is a device used to heat and sinter silica materials. Silica is an inorganic material with high stability, corrosion resistance and insulation properties. It is widely used in ceramic products, optical materials, semiconductor manufacturing and other fields. The structure and working principle of Silica vacuum sintering furnace are similar to silicon carbide sintering furnace. Silica High Temperature Sintering Furnace consists of furnace body, heating element, temperature control system and air conditioning system.

In the Silica sintering furnace, silica powder or granular materials are placed in the furnace body and heated to high temperatures for sintering. At high temperatures, chemical reactions and crystallization processes occur between silica particles, causing them to form dense bulk materials. During the sintering process, temperature and time are critical parameters that need to be adjusted according to specific material and application requirements.

The product advantages of Silicon Dioxide Sintering Furnace:

1. The furnace body of our Silica vacuum sintering furnace is made of high-temperature resistant materials that can withstand chemical reactions and thermal expansion in high-temperature environments.

2. This Silica High Temperature Sintering Furnace plays an important role in material preparation and industrial production due to its unique high temperature resistance and chemical stability.

3. This silica sintering furnace has strong environmental adaptability and can operate in different atmospheres.

4. This Silica vacuum sintering furnace heats and sinters silica materials.